Vacuum Pumps

Vacuum Pumps Structural characteristics

(1) overall structure of pump

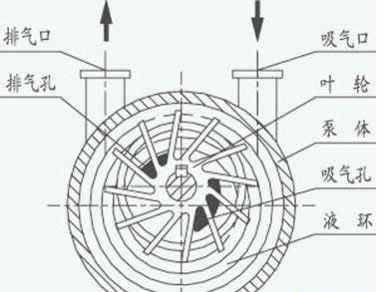

Liquid Ring Vacuum Pump Structural

The pump body layout of the vacuum pump determines the overall structure of the pump.

Vertical structure of the intake and exhaust level setting, assembly and connection pipes are more convenient.

But the pump’s center of gravity is higher and the stability is poor when running at high speed, so this type is mostly used in small pumps.

The air inlet of horizontal pump is above and the air outlet is below.

Sometimes, for easy connection of the vacuum system pipes, the vent can be connected from the horizontal direction, that is, the inlet and exhaust directions are perpendicular to each other.

At this point, the vent can be opened from left or right in both directions, with one end of the exhaust pipe connected to the other end or to the bypass valve.

This pump structure has low gravity and good stability when running at high speed.

General large, medium – sized pump more use this structure.

Two rotor shafts of the pump are installed perpendicular to the horizontal plane.

This kind of structure assembly gap is easy to control, rotor assembly is convenient, pump cover area is small.

But the pump center of gravity is higher and gear disassembly is not easy, the lubrication mechanism is also relatively complex.

(2) the transmission mode of the pump

The two rotors of the vacuum pump operate relatively synchronously through a pair of high-precision gears.

The driving shaft is connected to the motor through a coupling.

There are mainly two kinds of transmission structure arrangement: one is that the motor and gear are placed on the same side of the rotor as shown in the figure.

The driven rotor is driven by the motor end gear directly. In this way, the torsional deformation of the active rotor shaft is small, so the gap between the two rotors will not be changed due to the large torsional deformation of the active shaft. Therefore, the gap between the rotors is even in the running process.

The biggest shortcoming of this transmission mode is: a. there are three bearings on the driving shaft, which increases the processing and assembly difficulty of the pump, and the disassembly and adjustment of gear are also inconvenient;

B. The overall structure is uneven, and the pump’s center of gravity is in the direction of the motor and the side of the gear box.

The characteristics of

(1) within a wider pressure range, a larger pumping speed;

(2) the rotor has good geometrical symmetry, so the vibration is small and the operation is stable.

There are gaps between the rotor and between the rotor and the shell. Without lubrication, the friction loss is small and the driving power can be greatly reduced, thus the higher speed can be achieved.

(3) there is no need for oil seal and lubrication in the pump chamber, which can reduce the pollution of oil vapour on the vacuum system;

(4) no compression or exhaust valve in the pump chamber.

The structure is simple and compact, and is not sensitive to dust and water vapor in the exhaust gas;

(5) low compression, poor pumping efficiency of hydrogen gas;

(6) the rotor surface is a curved cylinder with complex shape, which is difficult to be processed and checked.

Vacuum pumps terminology

Definition of vacuum

A vacuum system is a thin volume of gas below the atmospheric pressure in the area

vacuum

The degree of thinness in a vacuum is usually expressed as “high vacuum” and “low vacuum”.

A high vacuum means good, and a low vacuum means poor.

Vacuum unit

Usually Torr is used, and Pa is used internationally.

1 holder =1/760 atmosphere =1 millimeter of mercury

The conversion of Tod and pa

1 pallet =133.322 pallets or 1 pallet =7.5 times 10-3 pallets

Mean free path

The mean distance passed by two successive collisions of gas particles in unregular thermal motion is denoted by the symbol “departure”.

traffic

The quantity of gas flowing through any section in unit time, expressed as “Q”, in units of Pa·L/s (Pa·L/s) or Torr·L/s (Torr·L/s).

The flow guide

Represents the ability of a vacuum pipeline to pass through a gas.

The unit is liters per second (L/s), and in a steady state, the pipe flow is equal to the pipe flow divided by the pressure difference between the two ends of the pipe.

The symbol is called U.

U = Q/(P2, P1)

pressure

The force applied by a gas molecule per unit area of the wall of the container is expressed as P.

Standard atmosphere

Pressure of 101325 dain per square centimeter, symbol :(Atm).

Ultimate vacuum

After the vacuum vessel is fully pumped, it is stabilized at a certain vacuum degree, which is called the ultimate vacuum.

Usually, the vacuum vessel must undergo air refining for 12 hours and then vacuum for 12 hours. The final hour is measured every 10 minutes. The average value of 10 times is taken as the limit vacuum value.

Extraction rate

At a certain pressure and temperature, the gas pumped from the pump inlet in unit time is called the pumping rate, or the pumping rate.

Sp=Q/ (p-p0).

How to choose a vacuum pump?

The vibration produced by the vacuum pump has no influence on the process and environment.

If the process is not allowed, the pump without vibration should be selected or anti-vibration measures should be taken.

The gaseous components are understood. The gaseous components are free from condensable vapors, particle dust and corrosive.

When choosing a vacuum pump, it is necessary to know the gas composition and select the corresponding pump for the extracted gas.

If the gas contains vapors, particles, and corrosive gases, it should be considered to install auxiliary equipment such as condensers, dedusters, etc.

The vacuum pump should be able to discharge all the gas produced in the process of vacuum equipment under its working pressure.

Correct combination of vacuum pumps.

Because vacuum pump has selectivity to take out air, accordingly, sometimes choose a kind of pump cannot satisfy take out air requirement, need a few kinds of pump to combine, complement each other ability to satisfy take out air requirement.

For example, titanium sublimation pump has high pumping speed for hydrogen, but cannot pump helium, and tripole sputter ion pump (or dipole type asymmetric cathode sputter ion pump) has a certain pumping speed for argon, and the combination of the two will make the vacuum device get better vacuum.

In addition, some vacuum pumps can not work under atmospheric pressure and need pre-vacuum.

Some vacuum pump outlet pressure is lower than atmospheric pressure, the need of the former pump, therefore, the pump needs to be combined to use.

Vacuum equipment requirements for oil pollution.

If the equipment is strictly required to be free of oil, various pumps should be selected, such as: water ring pump, molecular sieve adsorption pump, sputtering ion pump, cryogenic pump, etc.

If the requirements are not strict, the oil pump can be selected, and some anti-oil pollution measures, such as cooling well, baffle, oil trap, etc., can also meet the cleaning vacuum requirements.

Select the operating point of the vacuum pump correctly.

Each pump has a certain working pressure range, for example, the working pressure range of 2BV series water ring vacuum pumps is 760mmHg~25mmHg (absolute pressure). In such a wide pressure range, the pumping speed of the pump varies with the pressure (detailed changes refer to the performance curve of the pump), and the stable working pressure range is 760~60mmHg.

Therefore, the working point of the pump should be selected within this range, rather than allowing it to work for a long time under 25~30mmHg.

How does the oil vapor discharged from the vacuum pump affect the environment?

If the environment does not allow pollution, you can choose oil free vacuum pump, or exhaust oil steam outdoor.

The working pressure of the vacuum pump shall meet the requirements of the ultimate vacuum and working pressure of the vacuum equipment.

For example, a vacuum drying process requires a 10mmHg working vacuum, and the selected vacuum pump should have a maximum vacuum of at least 2mmHg, preferably 1mmHg.

Usually, the limit vacuum of the pump is half to one order of magnitude higher than the vacuum equipment.

Price, operation and maintenance of the vacuum pump.

Machinery installation

The vacuum pump should be installed on the ground in a strong place, the surrounding should be left with sufficient room for inspection, maintenance and maintenance.

The foundation should be kept level under the base of the vacuum pump. The four corners of the base are recommended to be installed with cushioning rubber or bolted to ensure the smooth operation of the vacuum pump and small vibration.

Sealing of the pipe connection of the vas vacuum pump and the system shall be reliable. For small vacuum pumps, metal pipe connection sealing gasket can be used for oil resistant rubber, and for small vacuum pumps, vacuum rubber pipe can be used for connection. The pipe diameter shall not be less than the suction diameter of the vacuum pump, and the pipe line shall be short and less elbow.

(during welding the pipe, the welding slag should be removed from the pipe. It is strictly forbidden to enter the vacuum pump chamber.)

In the connection pipeline, the user can install the valve and the vacuum gauge above the suction inlet of the vacuum pump to check the ultimate pressure of the vacuum pump at any time.

Solenoid is connected to power supply as per motor signage, ground wire and installed fuses and thermal relays of appropriate specifications.

Before the vacuum pump is put into use, it is necessary to remove the motor belt during the electrical test of the vacuum pump.

(turn direction as indicated by protective cover)

For vacuum pumps with cooling water, switch on cooling water as required.

If vacuum pump mouth installation electromagnetic valve, valve and vacuum pump should be simultaneous action.

When the exhaust gas of vacuum pump affects the working environment, oil mist filter can be installed at the exhaust port to lead off or install oil mist filter.

If you want to choose a high quality pump, we recommend baker and RIETSCHLE and BECKER vacuum pumps.