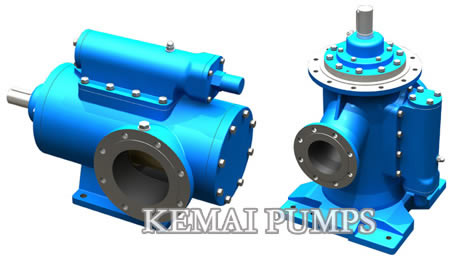

three screw pump types

Three screw pumps designed for oil applications of various temperatures in Petrochemical and Chemical factories, food and cereal processing, metallurgy, power station, building materials. Applicable to heavy oil, fuel, lubricant and similar liquids.

Three screw pump features

● For high temperature application, up to 150℃

● Applicable to non-corrosive lubricant liquids without solids. Ideal for fuel transfer, hydraulic engineering, heavy mechanic, marine engineering, printing & dying, chemical and petrochemicals.

● Mechanical seal, claw coupling. High and high efficiency operation with low noise and vibration.

● Stable of low without agitation and pulsation.

Three screw pumps application

It applies to deliver clean and non-corrosive medium which has lubricating troperty at temperature beow ≤150℃、with the viscosity of 5-760cSt,The pump’s working pressure range from 0.6MPa to 2.5MPa and flow capacity range from 0.6-123m3/h.

3G25X4 36X4 -46 three screw pump |

3G45X4-46 3 screw pump |

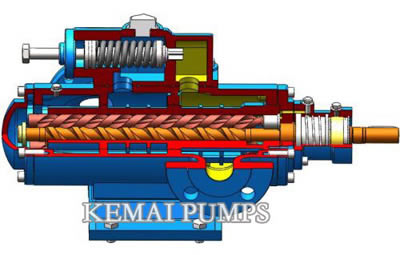

Three screw pumps feature

(1)Medium is delivered in axial direction continuously without agitation and pulsation.

(2)Small vibration and low noise

(3)High pressure and high efficiency

(4)Simple structure,easy disassembly and assembly

(5)Small volume and lighe weight

(6)Slight wear and long life of the pump

Structure:The pumps are sealed generally by mechanical seal and driven by the motor through the claw coupling.

Material: The driving and driven screw 16MnCrS5,40Cr,45,38CrMoALA Pump casing:HT200,QT450-10,ZCuSn10Pl,ZG270-500

Example of three screw pump model

Eg:3G25×4-46

3G:three screw pump

25:out-side dizmeter of the driving screw 25mm

4:potch number of the screw

46:46° pitch angle of the screw

R:hezvy fuel oil

r:light fuel oil

W:high temperature heated oil

N:high visc oil

A:code of design improvement

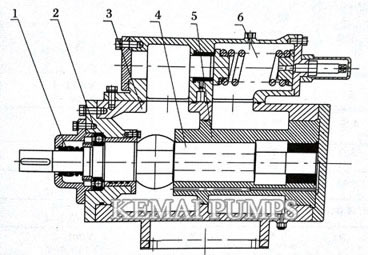

3G Series three screw pump structure:

structure 1 |

structure 2 |

1:Mechanical Seal

2:Rolling Bearing

3:Pump Casing

4:Screw

5:Pump Bush

6:Safty Valve

3 screw pump flow, head, power data table

| Type | Outlet

pressure |

Flow Q | Speed n r/min |

NPSHr

m |

Motor | ||

| m3/h | L/min | kw | type | ||||

| 25×4-46 | 1.0 | 0.8 | 13 | 1450 | 4 | 0.75 | Y802-4 |

| 2.5 | 0.6 | 10 | 1.5 | Y90L-4 | |||

| 1.0 | 2.0 | 33 | 2900 | 4.5 | 1.5 | Y90S-2 | |

| 2.5 | 1.6 | 26 | 3 | Y100L-2 | |||

| 30×4-46 | 1.0 | 1.6 | 26 | 1450 | 4.5 | 1.1 | Y90S-4 |

| 2.5 | 1.2 | 20 | 2.2 | Y100L1-4 | |||

| 1.0 | 3.6 | 60 | 2900 | 5 | 2.2 | Y90L-2 | |

| 2.5 | 3.2 | 53 | 4 | Y112M-2 | |||

| 36×4-46 | 1.0 | 2.8 | 46 | 1450 | 4.5 | 2.2 | Y100L1-4 |

| 2.5 | 2.4 | 40 | 4 | Y112M-4 | |||

| 1.0 | 6.5 | 108 | 2900 | 5 | 4 | Y112M-2 | |

| 2.5 | 6 | 100 | 7.5 | Y132S2-2 | |||

| 42×4-46 | 1.0 | 4.8 | 80 | 1450 | 5 | 4 | Y112M-4 |

| 2.5 | 4.2 | 70 | 5.5 | Y132S1-4 | |||

| 1.0 | 10.5 | 175 | 2900 | 5.5 | 5.5 | Y132S1-2 | |

| 2.5 | 10 | 166 | 15 | Y160M2-2 | |||

| 45×4-46 | 1.0 | 6.3 | 106 | 1450 | 5 | 3 | Y100L2-4 |

| 2.5 | 5.9 | 99 | 7.5 | Y132M-4 | |||

| 1.0 | 13.5 | 225 | 2900 | 5.5 | 7.5 | Y132S2-2 | |

| 2.5 | 13 | 217 | 15 | Y160M2-2 | |||

| 60×4-46 | 1.0 | 15.5 | 255 | 1450 | 5 | 11 | Y160M-4 |

| 2.5 | 14.5 | 245 | 15 | Y160L-4 | |||

| 1.0 | 32 | 533 | 2900 | 5.5 | 18.5 | Y160L-2 | |

| 2.5 | 31.5 | 525 | 37 | Y200L2-2 | |||

| 70×2-46 | 0.6 | 24 | 400 | 1450 | 5 | 7.5 | Y132M-4 |

| 1.0 | 23.5 | 390 | 11 | Y160M-4 | |||

| 1.6 | 22.5 | 370 | 15 | Y160L-4 | |||

| 70×4-46 | 1.0 | 24.5 | 408 | 1450 | 5 | 18.5 | Y180M-4 |

| 2.5 | 23.5 | 392 | 30 | Y200L-4 | |||

| 80×2-46 | 0.6 | 36.5 | 608 | 1450 | 5 | 11 | Y160M-4 |

| 1.0 | 35 | 594 | 18.5 | Y180M-4 | |||

| 1.6 | 34.5 | 575 | 22 | Y180L-4 | |||

| 80×4-46 | 1.0 | 37 | 617 | 1450 | 5.5 | 30 | Y200L-4 |

| 2.5 | 35 | 590 | 45 | Y225M-4 | |||

| 100×2-46 | 0.6 | 72.5 | 1208 | 1450 | 5 | 22 | Y180L-4 |

| 1.0 | 71 | 1183 | 37 | Y225S-4 | |||

| 1.6 | 60.5 | 1158 | 45 | Y225M-4 | |||

| 100×4-46 | 1.0 | 72.5 | 1208 | 1450 | 5.5 | 55 | Y250M-4 |

| 2.5 | 70 | 1165 | 75 | Y280S-4 | |||

| 100×3-27 | 0.6 | 72 | 1196 | 1450 | 6 | 22 | Y180L-4 |

| 1.6 | 70 | 1160 | 55 | Y250M-4 | |||

| 2.5 | 69 | 1145 | 75 | Y280S-4 | |||

| 120×3-27 | 0.8 | 123 | 2055 | 1450 | 6 | 55 | Y250M-4 |

| 1.5 | 120 | 2010 | 90 | Y280M-4 | |||

| 2.5 | 115 | 1920 | 132 | Y315M-4 | |||