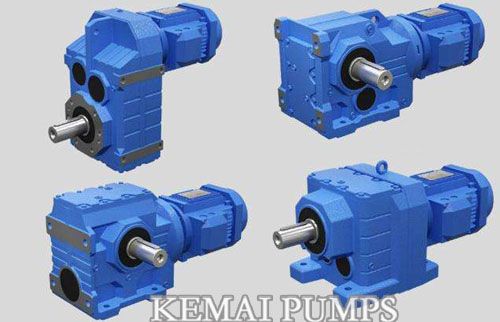

S Series Worm Helical Gear Motors

S Series Gear Motor Types

S series worm helical gear motor helical gear and worm gear are combined to improve the torque and efficiency of the machine.This series of products have complete specifications, wide range of rotating speed, good universality, suitable for various installation methods, safe and reliable performance and long life.The surface of the body has the function of heat dissipation, strong vibration absorption, low temperature rise, low noise.

*Product overview:

1. S series reducer has a high technology content, with helical gear and worm gear combined for integrated transmission to improve the torque and efficiency of the machine.

This series of products have complete specifications, wide range of rotating speed, good universality, suitable for various installation methods, safe and reliable performance and long life.

2. Concave and convex surfaces of the body have the function of heat dissipation, strong vibration absorption, low temperature rise and low noise.

3. The sealing performance of this machine is good and it has strong adaptability to the working environment.

4, S series gear motors speed reducer drive of high precision, especially adapt to work in places that have requirements of frequent start, can connect all kinds of gear reducer and configure various types of motor drive, can be installed in a 90 – degree transmission operation position.

5, S helical gear reducer adopts high wear-resisting material, key parts and pass by special heat treatment, with high machining precision, stable transmission, small capacity big, long service life, etc.

6. Helical gear reducer can be equipped with various types of motors, forming an electromechanical integration, which fully guarantees the quality characteristics of the product.

*Performance features:

1. Combination of helical gear and worm wheel, compact structure and large deceleration ratio.

2. Installation method: foot installation, hollow shaft installation, flange installation, torsion arm installation, small flange installation.

3. Input method: motor direct connection, motor belt connection or input shaft, connection flange input.

*Technical parameters:

Speed ratio range: basic type 9.96 ~ 244.74, S series /R series combination type can reach 8608

Torque range: 43 ~ 4200 Nm

Power range: 0.18 ~ 22 kW

*Structural form:

S-shaft extension joint SF-shaft extension, flange mounting

S…S- represents the axis input SA-shaft assembly type connection

SAF- shaft mounting, flange mounting